We use cookies on our website.

Some of them are necessary for the functioning of the site, but you can decide about others.

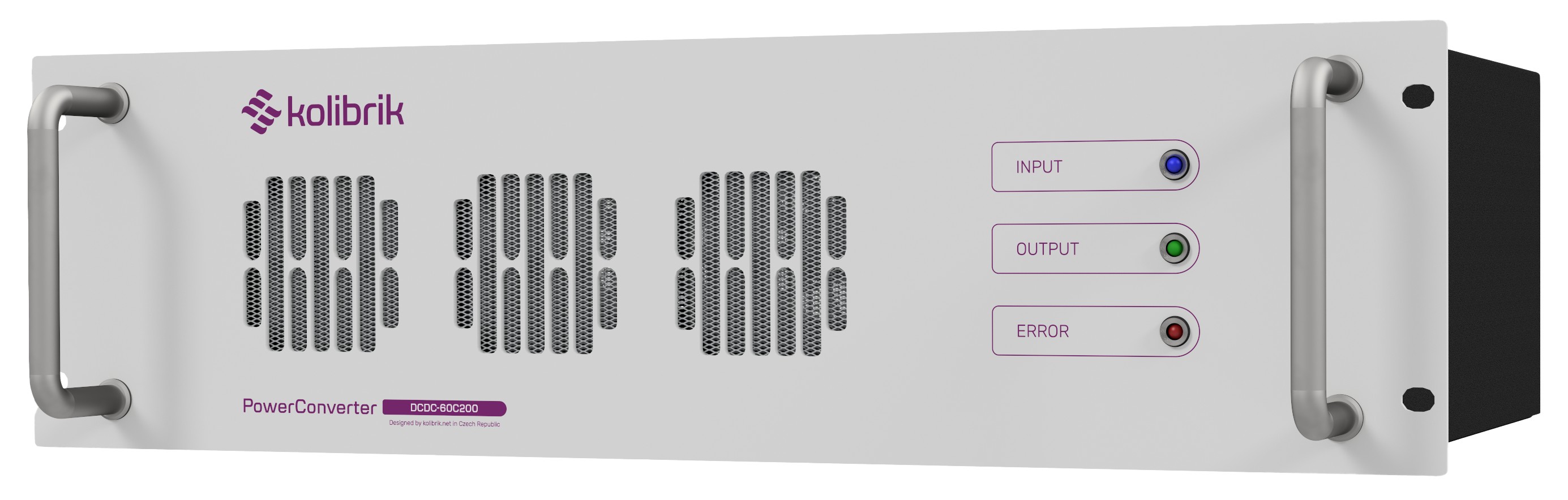

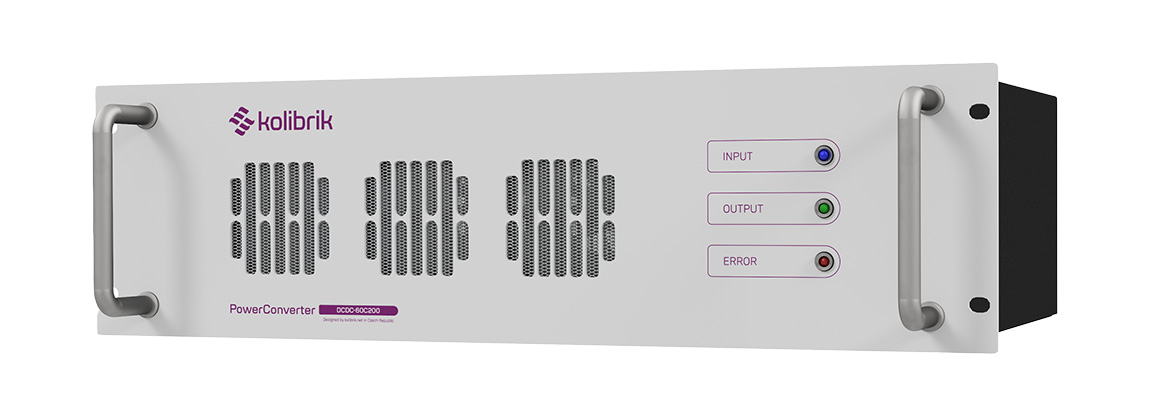

Kolibrik’s DCDC-M Product Family delivers precise, reliable power conversion with a robust architecture — built for versatile deployment across DC power applications, including fuel-cell stacks and other systems requiring modular conversion.

DCDC-M Product Family takes over where higher input voltages push DCDC-S to its limits— and where galvanic isolation between input and output is required.

The DCDC-M Product Family is designed for fast-moving projects — with short lead times and ready-to-use configurations. Whether you're building an application prototype, delivering a small production run, or setting up a training platform, DCDC-M gets you up and running without delays.

Uses 6 modules and fixed output settings — optimized for cost, speed, and plug-and-play simplicity.

Preconfigured design for lower cost, short lead times, and hassle-free installation — no custom setup needed.

Electrically isolated input and output for enhanced safety, noise reduction, and system protection.

Supports input voltages up to 144 V — ideal for demanding industrial and energy systems.

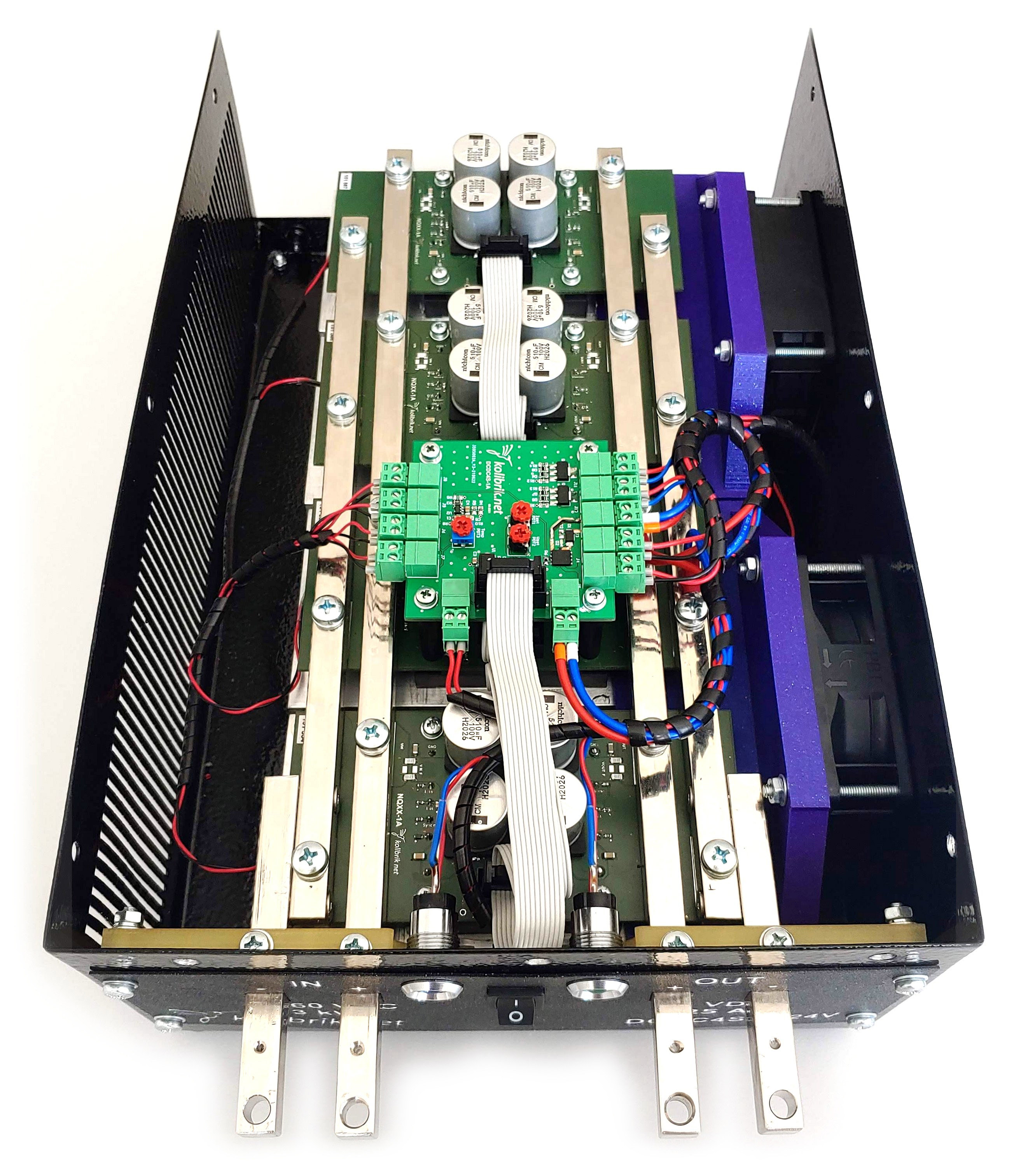

The DCDC-M Product Family is a DC/DC power conversion platform built for the diverse demands of hydrogen fuel cell and other applications. It’s based on standard industrial DC/DC converters — but enhanced with Kolibrik’s custom control electronics.

Out of the box, these converters aren’t designed to scale.

The DCDC-M Product Family includes one universal model — DCDC-M6-48/126 — designed to cover a broad range of typical use cases.

A custom-configurable variant is available for application-specific requirements.

Stand-alone DC/DC converter with fixed output

Preconfigured module with defined voltage and current parameters — ideal for consistent, repeatable use cases.

Open-frame setup for system integration

Bare-board version optimized for direct integration into existing power architectures or embedded designs.

Fully customized solutions for series production

Tailored hardware and control electronics for OEM projects, including thermal management, mechanical design, and digital interface integration.

The DCDC-M platform supports both constant voltage and current limitation.

| Cooling | Air |

| Design | Box |

| Input voltage | e.g. 72 … 144 V |

| Output voltage | 48 V |

| Max. input current | 92 A |

| Max. output current | 100 A |

| Max. power | 5 kW |

| Isolation | Isolated |

| Power | 5 kW |

| Efficiency | up to 97 % |

| Output control | Constant voltage |

| Control options | Fixed output settings |

From fuel-cell stacks to BoP and hybrid storage — precision power conversion across your hydrogen system.

Fuel-cell stack output power conversion for application power (e.g. fixed 24 V or 48 V output)

Powers pumps, valves, sensors and controls

Matches stack output to inverter input range

We offer DCDC-M models with custom-defined parameters, tailored mechanical and thermal setups, or as part of complete development services for custom projects and series production.

Need something specific? Just tell us your key requirements — input voltage and current ranges, and output current, preferred cooling method, and any other application-specific constraints — we offer customized solutions!

We don’t do one-size-fits-all. We offer: